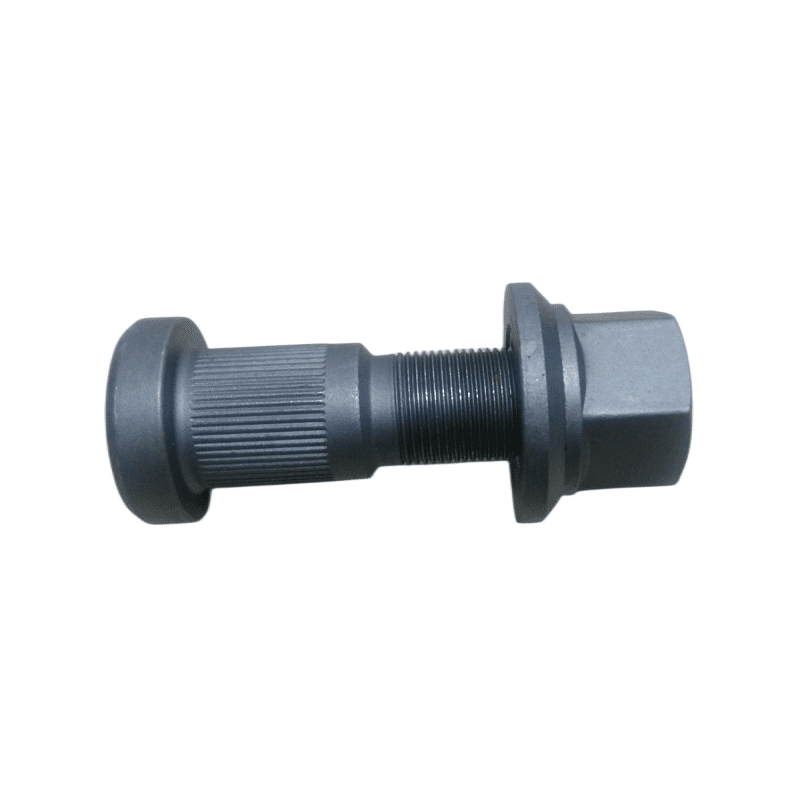

ROR Wheel Bolt 21220969 M22x1.5x95_104mm

Wheel Bolt for ROR Wheel Bolt

Hub bolts are high-strength bolts that connect vehicles to the wheels. The connection location is the hub unit bearing of the wheel! Generally, class 10.9 is used for mini-medium vehicles, class 12.9 is used for large-sized vehicles! The structure of the hub bolt is generally a knurled key file and a threaded file! And a hat head! Most of the T-shaped head wheel bolts are above 8.8 grade, which bears the large torsion connection between the car wheel and the axle! Most of the double-headed wheel bolts are above grade 4.8, which bear the lighter torsion connection between the outer wheel hub shell and the tire.

Specification

| Model | ROR Wheel Bolt with Wheel Nut |

| Reference No. | 21220969 |

| Thread Pitch | M22x1.5 |

| Length | 95_104mm |

| Quality | 10.9, 12.9 |

| Material | 40Cr, 42CrMo (ASTM5140, 4140) |

| Surface | Black Oxide, Phosphate |

| Logo | as required |

| MOQ | 3000pcs each model |

| Packing | neutral export carton or as required |

| Delivery Time | 15-40 days |

| Payment Terms | T/T, 30% deposit+70% paid before shipment |

More Models/Sizes Available for ROR Wheel Bolt (We make Strictly according to your drawings or samples)

| OEM | BRAND | M | L | L1 | H | Nut Size |

| 50 00 737 601 | ROR | M22x1.5 | 70 | 33 | 10 | SW32xH27 |

| 50 10 319 141 50 10 319 709 50 00 190 221 |

ROR | M22x1.5 | 79 | 40 | 10 | SW32xH27 |

| 50 10 241 892 | ROR | M22x1.5 | 113 | 50 | 10 | SW32xH27 |

| 50 10 439 317 50 00 190 220 50 00 654 139 15 30 054 101 |

ROR | M22x1.5 | 97 | 43 | 10 | SW32xH27 |

Features

| Hardness | 36-38HRC |

| Tensile Strength | ≥ 1140MPa |

| Ultimate Tensile Load | ≥ 346000N |

| Chemical Composition | C:0.37-0.44 Si:0.17-0.37 Mn:0.50-0.80 Cr:0.80-1.10 |

High-Strength Bolt Drawing

The purpose of the drawing process is to modify the size of the raw materials, and the second is to obtain the basic mechanical properties of the fastener through deformation and strengthening. If the distribution of the reduction ratio of each pass is not appropriate, it will also cause torsional cracks in the wire rod wire during the drawing process. In addition, if the lubrication is not good during the drawing process, it can also cause regular transverse cracks in the cold drawn wire rod. The tangent direction of the wire rod and the wire drawing die at the same time when the wire rod is rolled out of the pellet wire die mouth is not concentric, which will cause the wear of the unilateral hole pattern of the wire drawing die to aggravate, and the inner hole will be out of round, resulting in uneven drawing deformation in the circumferential direction of the wire, making the wire The roundness is out of tolerance, and the cross-sectional stress of the steel wire is not uniform during the cold heading process, which affects the cold heading pass rate.

Factory Introduction

The factory was founded in 1985, has more than 30 years of production and sales experience, 16 registered trademarks, has been recognized as "consumer trustworthy unit" by China Hebei Consumers Association for many consecutive years