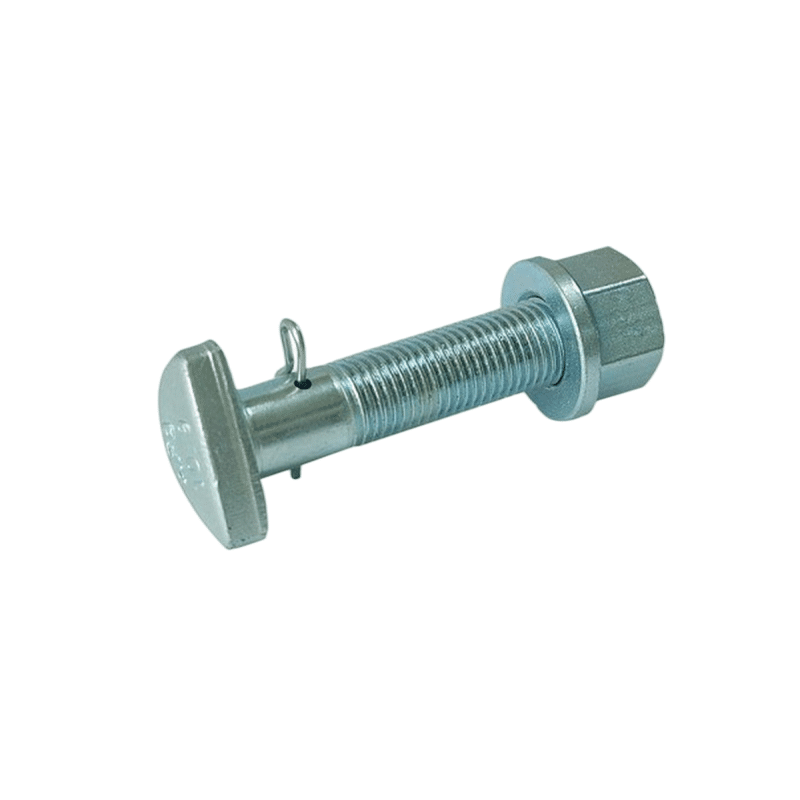

High strength Volvo Wheel Bolt 20515514

Features

| Hardness | 36-38HRC |

| Tensile Strength | ≥ 1140MPa |

| Ultimate Tensile Load | ≥ 346000N |

| Chemical Composition | C:0.37-0.44 Si:0.17-0.37 Mn:0.50-0.80 Cr:0.80-1.10 |

Specification

| Model | VOLVO Wheel Bolt with Wheel Nut |

| Reference No. | 20515514 |

| Thread Pitch | 7/8-14BSF |

| Length | 79-89mm |

| Quality | 10.9, 12.9 |

| Material | 40Cr, 42CrMo (ASTM5140, 4140) |

| Surface | Black Oxide, Phosphate |

| Logo | as required |

| MOQ | 3000pcs each model |

| Packing | neutral export carton or as required |

| Delivery Time | 15-40 days |

| Payment Terms | T/T, 30% deposit+70% paid before shipment |

More Models/Sizes Available for BPW Wheel Bolt (We make Strictly according to your drawings or samples)

| OEM | BRAND | M | L | L1 | H | Nut Size |

| 3112 593 3118 981 |

Volvo FM12, FM9 | 7/8-14UNF | 77 | 38 | 10 | SW33xH34 |

| 1573081 | Volvo | 7/8-14UNF | 84 | 33 | 10 | SW33xH34 |

| 3963 997 | Volvo | 7/8-14UNF | 94 | 40 | 10 | SW33xH34 |

| 157 3082 | Volvo | 7/8-14UNF | 102 | 40 | 10 | SW33xH34 |

| 157 3083 158 9009 158 9009 8 158 9010 |

Volvo | 7/8-14UNF | 111 | 40 | 10 | SW33xH34 |

| 8 398 432 8 152 104 |

Volvo | 7/8-14UNF | 114 | 40 | 10 | SW33xH34 |

Production Process: High-Strength Bolt Drawing

The purpose of the drawing process is to modify the size of the raw materials, and the second is to obtain the basic mechanical properties of the fastener through deformation and strengthening. If the distribution of the reduction ratio of each pass is not appropriate, it will also cause torsional cracks in the wire rod wire during the drawing process. In addition, if the lubrication is not good during the drawing process, it can also cause regular transverse cracks in the cold drawn wire rod. The tangent direction of the wire rod and the wire drawing die at the same time when the wire rod is rolled out of the pellet wire die mouth is not concentric, which will cause the wear of the unilateral hole pattern of the wire drawing die to aggravate, and the inner hole will be out of round, resulting in uneven drawing deformation in the circumferential direction of the wire, making the wire The roundness is out of tolerance, and the cross-sectional stress of the steel wire is not uniform during the cold heading process, which affects the cold heading pass rate.

Factory Introduction

The factory was founded in 1985. After years of development, the company has a very complete automated production line, which greatly reduces labor costs.

FAQ

1.What is your main products?

A.We are specialized in wheel bolts and nuts, u bolts, center bolt and spring pin etc.

B.We are manufacturer specialized in all kinds of auto parts

2.Where is your factory?

A.Our factory is located in rongqiao industrial area, liucheng street, nana’an, quanzhou city, fujian province in china

3.What is your MOQ?

A.For wheel bolts and nuts,need 3500 pcs per item

B.U bolt 300 pcs

C.Center bolt 1000 pcs

4.How is your quality?

A.10.9 GRADE

B.high quality

5.What is the finishing of your products?

A.BLACK/GREY PHOSPHATE

B.ZINC COATING

6.What is your advantage of your factory?

A.More than 20 years professional experience

B.Strong technology stuy team

C.Deliver to more than 50 countries