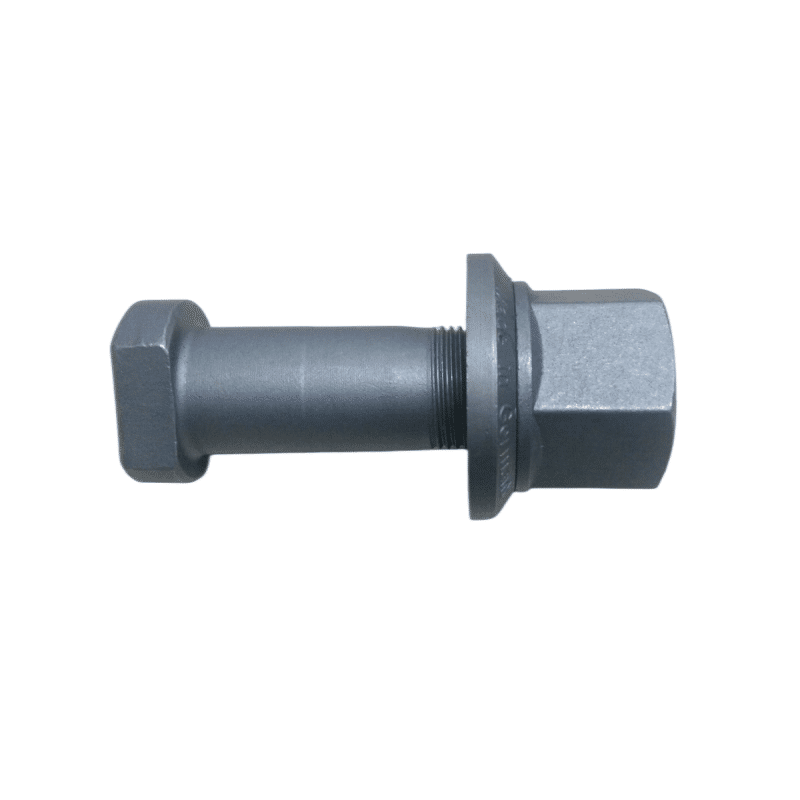

12.9 grade Iveco Wheel Bolt 42117459

Features

| Hardness | 39-42HRC |

| Tensile Strength | ≥ 1320MPa |

| Ultimate Tensile Load | ≥406000N |

| Chemical Composition | C:0.32-0.40 Si:0.17-0.37 Mn:0.40-0.70 Cr:0.15-0.25 |

Specification

| Model | IVECO Wheel Bolt with Wheel Nut |

| Reference No. | 42117459 |

| Thread Pitch | M22x1.5 |

| Length | 130-140mm |

| Quality | 10.9, 12.9 |

| Material | 40Cr, 42CrMo (ASTM5140, 4140) |

| Surface | Black Oxide, Phosphate |

| Logo | as required |

| MOQ | 3000pcs each model |

| Packing | neutral export carton or as required |

| Delivery Time | 15-40 days |

| Payment Terms | T/T, 30% deposit+70% paid before shipment |

More Models/Sizes Available for Iveco Wheel Bolt (We make Strictly according to your drawings or samples)

| OEM | BRAND | M | L | L1 | H | Nut Size |

| 42 117 445 420 648 18 420 648 19 |

Iveco Front | M22X1.5 | 65 | 38 | 9 | SW32xH27 |

| 42 117 446 | Iveco Front | M22X1.5 | 69 | 38 | 9 | SW32xH27 |

| 42 117 447 420 648 21 |

Iveco Front | M22X1.5 | 75 | 38 | 9 | SW32xH27 |

| 42 117 448 | Iveco Front | M22X1.5 | 78 | 40 | 9 | SW32xH27 |

| 42 117 449 716 8580 |

Iveco Front | M22X1.5 | 85 | 41 | 9 | SW32xH31 |

| 42 117 451 | Iveco Trakker, Front Iveco Stralis, Front |

M22X1.5 | 89 | 40 | 9 | SW32xH31 |

| 42 117 455 | Iveco Trakker, Rear Iveco Stralis, Rear |

M22X1.5 | 110 | 41 | 9 | SW32xH31 |

| 42 117 456 | Iveco | M22X1.5 | 115 | 40 | 9 | SW32xH31 |

| 42 117 457 | Euroteck Rear | M22X1.5 | 120 | 59 | 9 | SW32xH31 |

Production Process: Punching Machine

Punching Machine

At this stage of the process, heating up the whole steel to a point where it becomes malleable and then forming it in a die .

We can produce the unique logo according to the customer’s requiremnt during this process.

Advantage

The elements of the material are homogeneity and stability, make for easy heat treating and performance.

Quality Policy

Changjin are committed to meet customer’s expectation through continual improvements in all our various fasteners manufacturing processes and committed to improve our customer satisfaction level through supplying of quality products.

Factory Introduction

The factory was founded in 1985, has more than 30 years of production and sales experience, 16 registered trademarks, has been recognized as "consumer trustworthy unit" by China Hebei Consumers Association for many consecutive years.

FAQ

Q1 Do you offer OEM service?

Yes, we can offer OEM service.

Q2 What is your MOQ?

It depends on products, usually hub bolt MOQ 3500PCS,center bolt 2000PCS,u bolt 500pcs and so on.

Q3 What is your capacity of production?

We can produce more than 1500,000pcs bolts every month.

Q4 Where is your factory location?

We are in rongqiao industrial area, liucheng street, nan’an, quanzhou, Fujian, china.

Q5 How many heat treatment lines you have?

We have four advanced heat treatment lines.

Q6 What is your trade terms?

We can accept EXW, FOB, CIF and C and F.

Q7 How many countries you export?

We export to more than 100 countries, like Egypt, dubai, Kenya, Nigeria, sudan etc.